COFERMETAL designs and manufactures titanium products and equipment internally, in full cooperation with its clients, supporting and helping them in choosing the best solution to adopt for their necessity. The service offered by Cofermetal includes precision cutting of sheets, round and square bars, shearing and bending of plates, vacuum welding, MIG and TIG welding, spot welding, CNC milling, grinding, laser cutting and water jet cutting. The experience developed in the production of disks, frames and baskets allows us to obtain not only products of the highest quality but also to develop effective and efficient solutions.

Titanium Department

GALVANIC

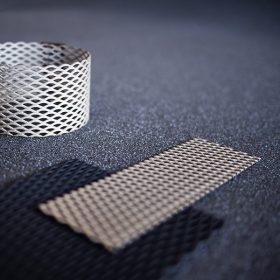

Internally designs and manufactures of a complete range of accessories for the Galvanic industry .

OXIDATION

Production of a wide range of discs, frames and bimetallic splines for the anodic oxidation market.

SEMI FINISHED PRODUCTS

Blooming activity, fed by a strong partnership with some of the most important Titanium manufacturers.

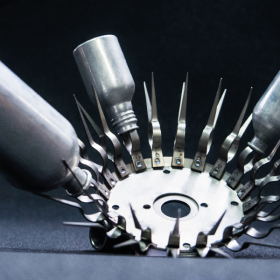

ANODES IN Ti/Pt AND MIXED OXIDES

Production of special anodes for the activation of chrome-plating baths and for precious metals recovery process.

Soldering Solutions

Cofermetal, thanks to the partnership with KOKI, of which it is exclusive distributor, offers a wide variety of Solder Pastes, flux-cored Wires and Soldering Fluxes which, together with the production of Solder Bars, guarantee high technological solutions. Supporting the customer in the choice of the most suitable product for their own process. Cofermetal also offers after-sales services, including periodic inspection of solder baths, laboratory analysis on all incoming raw materials and the issuance of the Conformity Certificate for each production batch, which attests the respect of the UNI reference regulations and the specific specifications of the customers.